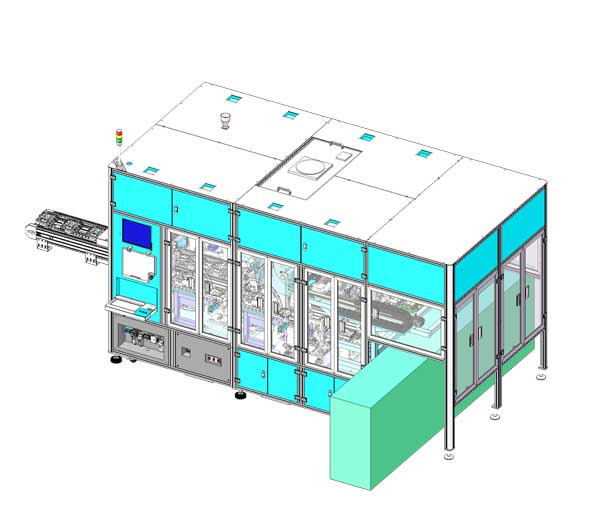

The pole group coating machine mainly covers the appearance of the incoming pole group, which is compatible with the bottom coating of the unilateral outlet lug - pole ear bending type product and the surrounding coating of the bilateral outlet lug type product. Then, there is no adhesive detection, and the robot picks out the NG product to detect.

1, the use of servo glue, glue length can be freely controlled. There is tension control during the gluing process to ensure that the adhesive paper does not rebound, fold or wrinkle after gluing is completed, and the adhesive paper passes through the correction mechanism to ensure the accurate adhesion of the adhesive.

2. The moment of the rolled rubber paper is controlled by the precision pressure regulator of the cylinder.

3, the use of elastic rubber roller paste adhesive paper, to prevent the battery damage.

4, the rubber preparation mechanism adopts quick change design, easy to clean and replace, the cutting blade is designed to be hidden.